Timing Pulleys & Flanges

For a smaller system size, and higher power density needs, timing belt pulley is always a good choice. At Goodwill, we carry a wide range of timing pulleys with various tooth profiles including MXL, XL, L, H, XH, 3M, 5M, 8M, 14M, 20M, T2.5, T5, T10, AT5, and AT10. Plus, we offer customers the option to select a tapered bore, stock bore, or QD bore, ensuring we have the perfect timing pulley for your specific requirements.As part of a one-stop purchasing solution, we make sure to cover all bases with our complete range of timing belts that mesh perfectly with our timing pulleys. We can even fabricate custom timing pulleys made from aluminum, steel, or cast iron to meet individual customer needs.

Regular material: Carbon steel / Cast iron / Aluminum

Finish: Black oxide coating / Black phosphate coating / With anti-rust oil

Durability, Precision, Efficiency

Material

The most common forms of timing pulley failure are tooth wear and pitting, which can be caused by a lack of adequate wear resistance and contact strength. To avoid these problems, Goodwill selects only the best materials to meet the diverse needs of our customers - carbon steel, aluminum and cast iron. Carbon steel has higher wear resistance and force resistance, but the wheel body is heavier and is used in heavy-duty transmissions. Aluminum is lighter in weight and works well in light duty timing belt drives. And cast iron ensures that the timing belt pulleys are subjected to higher stresses.

Process

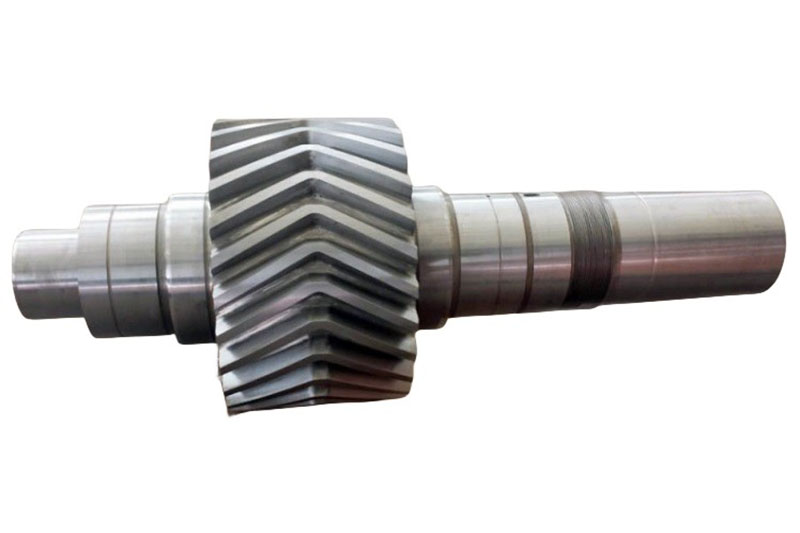

All Goodwill timing pulleys are precision machined to ensure accurate timing and minimal wear. The teeth are carefully aligned to prevent slippage and ensure the pulleys can withstand the stress of high-speed, heavy-duty applications. We also ensure that each pulley is designed to fit the correct belt size to ensure proper tension and reduce unnecessary wear.

Surface

At Goodwill, we are constantly striving to improve the quality and performance of timing pulleys while controlling production and maintenance costs. That's why we offer a range of surface treatments for timing pulleys to enhance their durability, corrosion resistance and visual appeal. Our finishes include black oxide, black phosphate, anodizing and galvanizing. These are all proven ways to improve the surface of the synchronous pulley and prolong its service life.

Flanges

Flanges play a crucial role in preventing belt jumping. Generally, in a synchronous drive system, the smaller timing pulley should be flanged, at least. but there are exceptions, when the center distance is greater than 8 times the diameter of the smaller pulley, or when the drive is operating on a vertical shaft, both timing pulleys should be flanged. If a drive system contains three timing pulleys, you need to flange two, while flanging each one is crucial for more than three timing pulleys.

Goodwill provides a full range of flanges designed specifically for the three series timing pulleys. We understand that every industrial application is unique, and that’s why we also provide custom flanges as per your request.

Regular material: Carbon steel / Aluminum / Stainless Steel

Flange

Flanges for timing pulleys

Goodwill's Timing Pulleys are used in a wide variety of industrial applications. Our Timing Pulleys are designed to ensure high-precision synchronization, allowing machines and equipment to run smoothly and efficiently without any slippage or misalignment. Our products are widely used in CNC machine tools, printing and packaging equipment, textile machinery, conveying systems, automobile engines, robots, electronic equipment, food processing equipment, medical equipment and other industries. With years of experience in the industry, we have built a solid reputation for producing high quality Timing Pulleys that are both durable and reliable. Choose Goodwill for superior performance and long-lasting durability in your industrial applications.