In addition to standard parts, we offer a range of products tailored specifically for the agricultural machinery industry.

Speed Reducers For Pumping Units

Speed Reducers are used for conventional beam pumping units, designed, manufactured, and inspected strictly according to SY/T5044, API 11E, GB/T10095 and GB/T12759.

Features:

Simple Structure; High Reliability.

Easy Installation & Maintenance; Long Service Life.

Goodwill's speed reducers are welcomed by customers of oilfields in Xinjiang, Yan'an, North China and Qinghai.

Gearbox Housings

Superior casting capability and CNC machining capability, ensures Goodwill qualified to provide various kinds of made-to-order gearbox housings.

Goodwill also provides machined gearbox housings on request, besides providing the full set of assembled units, such as gears, shafts, etc.

Casing Head

Components: Casing Head Spool, Reducing Jacket, Casing Hanger, Body of Casing Head, Base.

Designed, manufactured, and inspected in strict accordance with API Spec6A/ISO10423-2003 Standard.

All pressure parts are made of high quality alloy steel forgings, and undergo the non-destructive detection and heat treatment to ensure enough strength. Therefore, all these parts can be in safe operation under the pressure of 14Mpa-140Mpa.

Choke Kill Manifold

Choke Kill Manifold is an important equipment to prevent blowout, control pressure changes of the oil and gas well, and guarantee the continuous operation of the imbalanced drilling.

Performance Parameter:

Specification Level: PSL1, PSL3

Performance Level: PR1

Temperature Level: Level P and Level U

Material Level: AA FF

Operative Norm: API Spec 16C

Spec. & Model:

Nominal Pressure: 35Mpa 105Mpa

Nominal Diameter: 65 103

Control Mode: Manual and Hydraulic

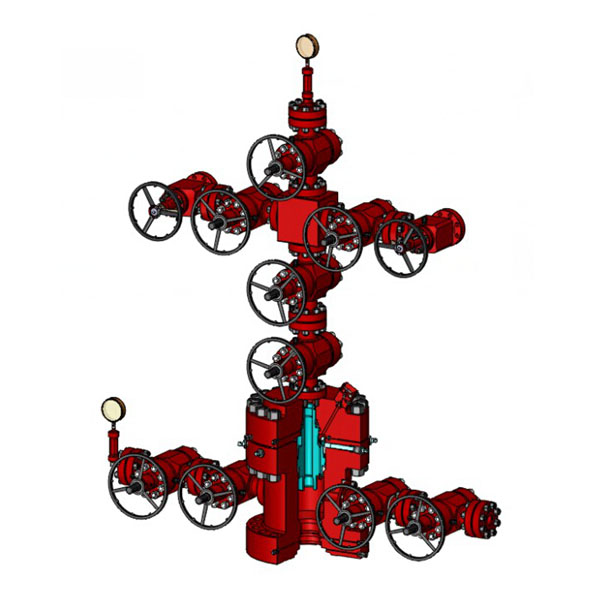

Tubing Head & Christmas Tree

Components: Christmas Tree Cap, Gate Valve, Tubing Head Transform Connection Equipment, Tubing Hangeer, Tubing Head Spool.

Designed, manufactured, and inspected in strict accordance with API Spec6A/ISO10423-2003 Standard.

All pressure parts are made of high quality alloy steel forgings, and undergo the non-destructive detection and heat treatment to ensure enough strength. Therefore, all these parts can be in safe operation under the pressure of 14Mpa-140Mpa.