The use of mechanical methods to transmit power and motion is known as mechanical transmission. Mechanical transmission is classified into two types: Friction transmission and meshing transmission. Friction transmission uses friction between mechanical elements to transmit power and motion, including belt transmission, rope transmission, and friction wheel transmission. The second type of transmission is meshing transmission, which transmits power or motion by engaging the drive and driven parts or by engaging the intermediate parts, including gear transmission, chain transmission, spiral transmission, and harmonic transmission, etc.

Belt transmission is made up of three components: a drive pulley, a driven pulley, and a tensed belt. It relies on the friction or mesh between the belt and pulleys to achieve movement and power transmission. It is classified into flat belt drive, V-belt drive, multi-v belt drive, and synchronous belt drive based on the shape of the belt. According to the use, there are general industrial belts, automotive belts, and agricultural machinery belts.

1. V-belt Drive

V-belt is a generic term for a loop of belt with a trapezoidal cross-sectional area, and a corresponding groove is made on the pulley. During working, the V-belt only makes contact with two sides of the pulley groove, i.e. the two sides are the working surface. According to the principle of groove friction, under the same tensioning force, the friction force generated is greater, the power transferred is greater, and a greater transmission ratio can be achieved. V belt drive has a more compact structure, easy installation, high transmission efficiency, and low noise. It is primarily used in electric motors and internal combustion engines.

2. Flat Belt Drive

The flat belt is made of several layers of adhesive fabric, with edge wrapping and raw edge options. It has great tensile strength, preload retention performance,and moisture resistance, but it is poor in overload capacity, heat and oil resistance, etc. To avoid uneven force and accelerated damage, the joint of the flat belt should ensure that the perimeter of both sides of the flat belt is equal. Flat belt drive has the simplest structure, and the pulley is simple to manufacture, and widely used in the case of large transmission center distance.

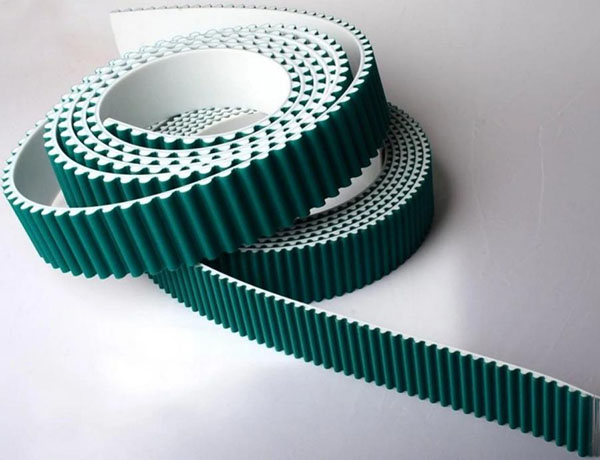

3. Synchronous Belt Drive

Synchronous belt drive consists of a loop of belt with equally spaced teeth on the inner circumference surface and pulleys with matching teeth. It combines the advantages of belt drive, chain drive, and gear drive, such as precise transmission ratio, no-slip, constant speed ratio, smooth transmission, vibration absorption, low noise, and a wide transmission ratio range. However, when compared to other drive systems, it requires higher installation accuracy, has a strict center distance requirement, and is more expensive.

4. Ribbed Belt Drive

Ribbed belt is a flat belt base with evenly spaced longitudinal 40°trapezoidal wedges on the inner surface. Its working surface is the wedge's side. Ribbed belt has the characteristics of small transmission vibration, fast heat dissipation, smooth running, small elongation, large transmission ratio, and highly linear velocity, resulting in a longer life, energy savings, high transmission efficiency, compact transmission, and occupying little space. It is mainly used in situations requiring high transmission power while maintaining a compact structure, and also be used in the transmission of large load variation or impact load.

Chengdu Goodwill, a company that has been in the mechanical transmission parts industry for decades, provides a comprehensive range of timing belts, V-belts, and matching timing belt pulleys, V-belt pulleys to the worldwide. For more information about the products we offer, please contact us by phone +86-28-86531852, or by email export@cd-goodwill.com

Post time: Jan-30-2023