1.Types of Chain Drive

Chain drive is divided into single row chain drive and multi-row chain drive.

● Single Row

The links of single-row heavy-duty roller chains are divided into inner links, outer links, connecting links, cranked links and double cranked links according to their structural forms and component names.

● Multi-Row

The multi-row heavy-duty roller chain links, in addition to having the same inner links as the single-row chain, are specified to include multi-row outer links, multi-row connecting links, multi-row cranked links, and multi-row double cranked links according to their structural forms and the names of the components.

2.Structure of Chain Plate

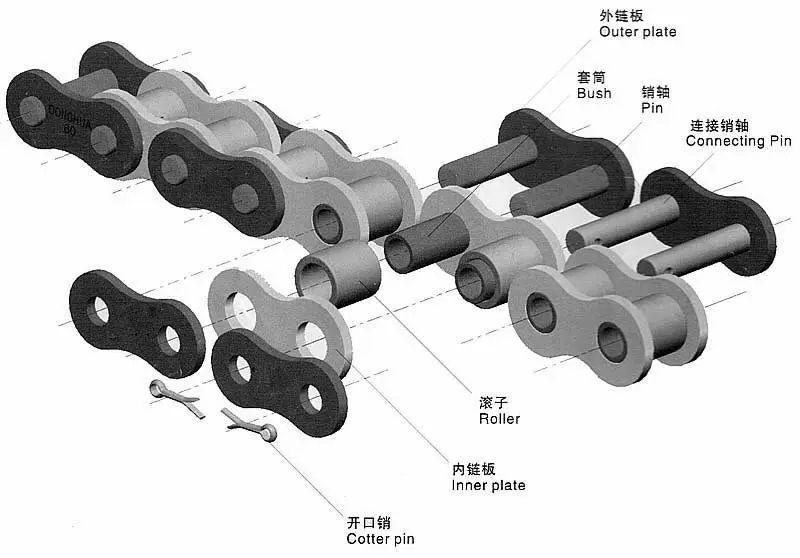

The chain plate structure mainly includes chain plates, rollers, pins, bushings, etc. The pin is a type of standardized fastener that can be used for static fixed connection and relative movement relative to the connected components.

3.Mechanical Transmission Chain and Chain Wheel

● Roller Chain

The roller chain is composed of outer links and inner links articulated together. The pin and outer link plate, as well as the bushing and inner link plate, form a static fit; the pin and bushing form a dynamic fit. The roller freely rotates on the bushing to reduce friction and wear during engagement, and to cushion impact. It is mainly used for power transmission.

● Double Pitch Roller Chain

The double pitch roller chain has the same dimensions as the roller chain, except that the pitch of the chain plates is twice that of the roller chain, resulting in reduced chain weight. It is used in medium to light load, medium to low-speed, and large center distance transmission devices, and can also be used in conveying equipment.

● Toothed Chain

Toothed chain is composed of several sets of toothed chain plates arranged in an interlocking manner and connected by hinge chains. The working surfaces on both sides of the chain plate are straight, with an angle of 60°, and the transmission is achieved by the engagement between the working surface of the chain plate and the teeth of the sprocket. The hinge chain forms are divided into three types: cylindrical pin type, bushing type, and roller type.

● Sleeve Chain

The sleeve chain has the same structure and dimensions as the roller chain, except without rollers. It is lightweight, cost-effective, and can improve pitch accuracy. To enhance load-bearing capacity, the space originally occupied by the rollers can be utilized to increase the size of the pins and sleeves, thereby increasing the pressure-bearing area. It is used for infrequent transmission, medium to low-speed transmission, or heavy-duty equipment (such as counterweights, forklift lifting devices), etc.

● Cranked Link Chain

The cranked link chain has no distinction between inner and outer chain links, and the distance between chain links remains relatively uniform even after wear. The curved plate increases the elasticity of the chain and provides good impact resistance. There is a larger gap between the pin, sleeve, and chain plate, requiring lower demands for the alignment of sprockets. The pin is easy to disassemble and assemble, facilitating maintenance and adjustment of the chain slack. This type of chain is used for low-speed or extremely low-speed, high-load, open transmission with dust, and in locations where the two wheels are not easily aligned, such as the walking mechanism of construction machinery like excavators and petroleum machinery.

● Formed Chain

The chain links are processed using forming tools. The formed chain links are made of malleable cast iron or steel, and are easy to assemble and disassemble. They are used for agricultural machinery and transmissions with chain speeds below 3 meters per second.

● Chain Wheel of Roller Chain

The basic parameters of roller chain sprockets include the pitch of the chain, the maximum outer diameter of the bushing, the transverse pitch, and the number of teeth. Sprockets with small diameters can be made in a solid form, those of medium size can be made in a web form, and those with large diameters can be made in a combination form, where a replaceable toothed ring is bolted to the core of the sprocket.

● Chain Wheel of Toothed Chain

The distance from the lowest point of the tooth profile working segment to the pitch line is the main meshing dimension of the toothed chain sprocket. Sprockets with small diameters can be made in a solid form, those of medium size can be made in a web form, and those with large diameters can be made in a combination form.

Post time: Jul-25-2024