Gears & Racks

Goodwill’s gear drive manufacturing capabilities, backed by more than 30 years of experience, are ideally suited high-quality gears. All products are made using cutting-edge machinery with an emphasis on efficient production. Our gear selection ranges from straight cut gears to crown gears, worm gears, shaft gears, racks and pinions and more. No matter what type of gear you need, whether it’s a standard option or a custom design, Goodwill has the expertise and resources to build it for you.

Regular material: C45 / Cast iron

With / Without heat treatment

Precision, Sturdiness, Dependability

Goodwill is a company committed to delivering high quality gear that exceeds customer expectations. We know gears are an integral part of many industrial applications and their performance can be the difference between success and failure. That's why we pride ourselves on being able to manufacture the highest quality gear. Our commitment to quality begins with our design process. Our team of highly skilled engineers use the latest CAD software and 3D modeling tools to simulate various load and stress conditions to ensure our gears are precisely designed to withstand the harshest operating environments. We also utilize advanced gear design software to calculate gear parameters, ensuring our gears are optimized for maximum performance. When manufacturing our gears, we use only the best materials and equipment. We have a wide range of high-quality raw materials available, including various types of steel, cast iron. We also have a team of highly skilled machinists who use the latest CNC machines to cut, shape and finish our gears to the exact specifications required. Our state-of-the-art equipment allows us to achieve tight tolerances and maintain consistency across our product line. The durability of our gear is another area where we excel. We utilize advanced heat treatment methods to maximize wear resistance and impact load capacity. This ensures our gears can withstand long periods of use under the most demanding conditions. We pride ourselves on being able to manufacture gears designed for maximum efficiency. We utilize state-of-the-art inspection equipment to measure pitch, runout and misalignment to ensure our gears are precisely aligned and meshed for maximum efficiency. Goodwill has a reputation for producing the highest quality gear. Our commitment to excellence begins with our design process and extends throughout our manufacturing process.

Standard Gears Specifications

|

Spur Gears

|

Bevel Gears

|

Worm Gears

|

Racks

|

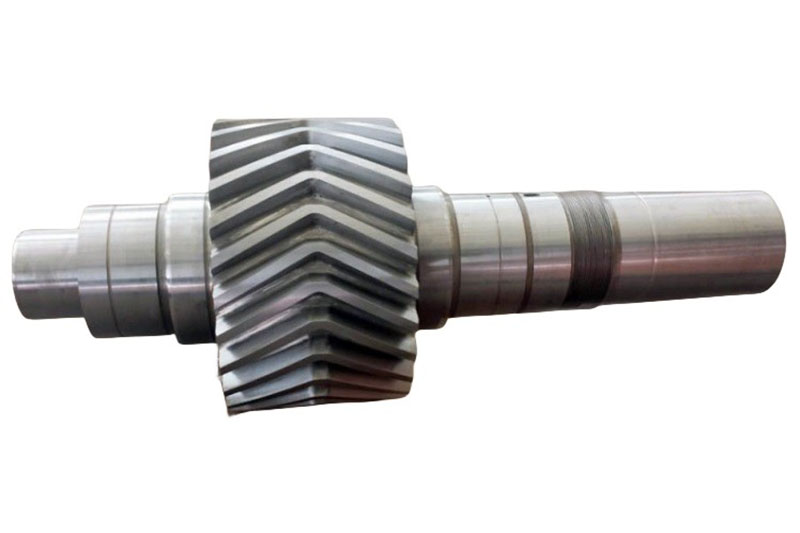

Shaft Gears

|

| Pressure Angle: 14½°, 20° Module No. : 1, 1.5, 2, 2.5, 3, 4, 5, 6 Bore Type: Finished Bore, Stock Bore |

Pressure Angle: 20° Ratio: 1, 2, 3, 4, 6 Bore Type: Finished Bore, Stock Bore |

Bore Type: Finished Bore, Stock Bore Case Hardened: Yes / No Made-to-order Worm Gears are also available on request. |

Pressure Angle: 14.5°, 20° Diametal Pitch: 3, 4, 5, 6, 8, 10, 12, 16, 20, 24 Length (inch): 24, 48, 72 Made-to-order racks are also available on request. |

Material: Steel, Cast Iron Made-to-order shaft gears are also available on request. |

Conveyor systems, reduction box, gear pumps and motors, escalator drives, wind-tower gearing, mining, and cement are some of the industries we work with.We recognize that each customer has unique needs, and we are committed to working with you to develop a solution that meets your technical requirements and budget. When you choose Goodwill for your gear manufacturing needs, you can rest assured that you are working with a company that is committed to your success. Our team of experienced professionals is dedicated to providing exceptional service and support, from initial design and prototyping to final production and delivery. So if you are looking for a reliable and experienced gear manufacturer, look no further than Goodwill. Contact us today to learn more about our capabilities and how we can help you achieve your goals.